Glass Manufacturing in Australia

The history of glass predates human records and yet glass making technology is continually evolving. High performance glass is a relatively recent innovation.

Early Glass Making History

Glass-like substances occur naturally and have been used by humans for generations. The best known is obsidian, produced by the intense heat of volcanoes. It is thought that seagoing Mediterranean merchants accidentally combined soda, sand and limestone in campfires and noticed the hard and clear substance left in the ashes. Egyptians established the first known glass factory around 1400 BC.

By 500AD, the Roman empire had spread glass-making techniques throughout the Mediterranean and into northern Europe and Britain. For centuries, flat glass was produced by blowing a large bubble of molten glass at the end of a metal tube and beating the heated result flat. The blown cylinder process continued to be developed until the mid 19th century.

Modern Glass Making

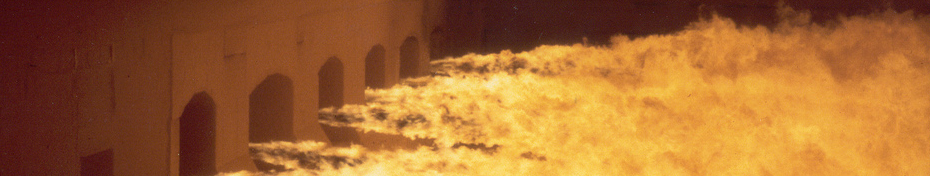

In the early 20th century, techniques were developed to draw molten glass into sheets and mechanically polish them on both sides. This process met the demand for modern building and automotive glass, but was replaced in 1959 when Pilkington Brothers introduced the Float Glass process which now accounts for ninety percent of the world’s flat glass (invented by Sir Alastair Pilkington in 1952).

Glass Making in Australia

Glass making in Australia began soon after European settlement, but flat glass manufacture didn’t commence until 1935 with Viridian’s predecessors first sheet glass plant in Sydney. Float glass technology was introduced in Australia in 1974 with the first float glass plant in the southern hemisphere at Dandenong in Victoria.

State-Of-The-Art Performance Glass

Coatings make profound changes in the optical properties of glass and are applied by advanced high temperature technology to the cooling ribbon of glass. The on-line chemical vapour deposition (CVD) of coatings is the most significant advance in the float process since it was invented. CVD can be used to lay down a variety of coatings less than a micron thick, to reflect visible and infrared wavelengths such as Low E energy efficient glass. Multiple coatings can be deposited in the few seconds available as the glass ribbon flows beneath the coaters to produce a chemically/photo-active layer that is far more durable than other post-production coating technologies. The first CVD coater of its type in the Southern Hemisphere, for the production of energy efficient coated glass, was commissioned by Viridian at the Dandenong plant in 2009. Australia is a world-leader in the production of high performance quality glass product.